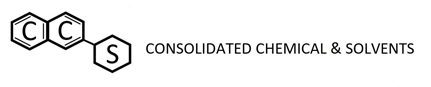

Dibutyl Phthalate (DBP) – High Purity Industrial-Grade Solvent

$14.99 – $29.99

Chemical Identity:

- Chemical Name: Dibutyl Phthalate

- Synonyms: DBP

- Molecular Formula: C16H22O4

- Molecular Weight: 278.35 g/mol

- CAS Number: 84-74-2

- EC Number: 201-557-4

Physical and Chemical Properties:

- Appearance: Clear, colorless to light yellow liquid

- Odor: Slight characteristic odor

- Purity: [Specify, e.g., 99% or higher]

- Density: 1.04–1.05 g/cm³ at 20°C

- Boiling Point: 340°C (644°F)

- Melting Point: −35°C (−31°F)

- Flash Point: 157°C (315°F) (Closed cup)

- Vapor Pressure: <0.01 mmHg at 20°C

- Solubility: Insoluble in water; soluble in organic solvents (e.g., alcohols, ketones, ethers).

Description

Dibutyl Phthalate (DBP) is a high-purity industrial chemical renowned for its versatility and reliability. As a superior plasticizer and solvent, DBP is widely used in the manufacturing of flexible PVC, rubber materials, and a variety of industrial coatings and adhesives. Its excellent plasticizing properties ensure optimal flexibility and durability in polymer products.

Our Dibutyl Phthalate is carefully packaged to ensure safe handling and transportation. Available in multiple sizes to suit your needs, whether for laboratory experiments or industrial applications.

Applications of Dibutyl Phthalate (DBP):

- Plastic Manufacturing:

- Used as a plasticizer in the production of flexible polyvinyl chloride (PVC) products, enhancing flexibility, durability, and workability.

- Found in items like cables, hoses, synthetic leather, and other flexible plastic goods.

- Paints and Coatings:

- Acts as a solvent and plasticizer in industrial and decorative paints.

- Improves flow, flexibility, and resistance to cracking in coatings.

- Adhesives and Sealants:

- Enhances flexibility, strength, and adhesion in formulations for industrial adhesives and sealants.

- Printing Inks:

- Used as a solvent and additive in printing ink formulations, ensuring smooth application and preventing cracking.

- Synthetic Rubber:

- Plasticizes synthetic rubber, improving flexibility, elasticity, and resistance to wear.

- Cosmetics and Personal Care (Restricted/Regulated):

- Historically used in some cosmetic formulations like nail polish to prevent cracking, though its use in cosmetics is now regulated or banned in many regions.

- Resins and Polymer Processing:

- Acts as a processing aid in polymer resin formulations, improving flow and shaping capabilities.

- Laboratory and Research Applications:

- Employed as a solvent or plasticizing agent in chemical synthesis and experimental setups.

- Automotive Applications:

- Found in automotive undercoatings, vinyl upholstery, and dashboard plastics to improve material durability and flexibility.

Storage:

- Store in a cool, dry, well-ventilated area (15–30°C), away from direct sunlight and heat.

- Use tightly sealed, chemical-resistant containers with proper labels.

- Keep away from oxidizers, acids, bases, and food-related areas.

- Use spill containment systems to manage leaks.

Handling:

- Wear appropriate PPE: gloves, goggles, chemical-resistant clothing, and respirators in poorly ventilated areas.

- Handle in well-ventilated spaces or under a fume hood.

- Avoid direct contact; wash hands thoroughly after use.

- Keep safety equipment (eyewash stations, safety showers) nearby.

- Clean spills immediately using absorbents and dispose of waste properly.

Disposal:

- Dispose of DBP and contaminated materials per local hazardous waste regulations. Use licensed disposal services if necessary.

Additional information

| Size | 100mL (3.3 Fl Oz), 250mL (8 Fl Oz), 500mL (16 Fl Oz) |

|---|

Related products

-

Valencene | Natural Citrus Aroma Compound

$17.00 – $79.99 Select options This product has multiple variants. The options may be chosen on the product page -

Methyl Alcohol (Methanol) – Premium Multi-Purpose Solvent

$12.99 – $70.00 Select options This product has multiple variants. The options may be chosen on the product page -

Isopropyl Myristate (IPM) – Premium Grade Emollient

$14.99 – $45.00 Select options This product has multiple variants. The options may be chosen on the product page -

Polyethylene Glycol 400 (PEG 400)

$19.99 – $285.00 Select options This product has multiple variants. The options may be chosen on the product page

SKU: N/A

Category: Solvents (3)

Tags: Chemical-Grade DBP Supplier, Chemical-Grade Dibutyl Phthalate, Custom Packaging Dibutyl Phthalate, DBP Chemical Additive, DBP Chemical Compatibility, DBP for Adhesive Formulations, DBP for Chemical Synthesis, DBP for Coatings and Paints, DBP for Flexible Polymers, DBP for Flexible Vinyl, DBP for Laboratory Applications, DBP for Material Testing, DBP for Paint Formulations, DBP for Plastic Manufacturing, DBP for Printing Inks, DBP for Rubber Compounds, DBP for Synthetic Rubber, DBP in Industrial Applications, DBP Industrial Use, DBP Plasticizer, DBP Solvent for Industrial Coatings, Dibutyl Phthalate, Dibutyl Phthalate Bulk Supply, Dibutyl Phthalate Chemical Agent, Dibutyl Phthalate Exporter, Dibutyl Phthalate for Polymers, Dibutyl Phthalate for PVC Production, Dibutyl Phthalate for Resins, Dibutyl Phthalate MSDS, Dibutyl Phthalate Online Supplier, Dibutyl Phthalate Packaging, Dibutyl Phthalate Price Per Liter, Dibutyl Phthalate Safety Data Sheet, Dibutyl Phthalate Shipping Regulations, Dibutyl Phthalate Uses in Manufacturing, Dibutyl Phthalate Wholesale, Eco-compliant DBP Alternatives, Eco-Friendly Dibutyl Phthalate Substitute, Flexible PVC Plasticizer, High-Purity Dibutyl Phthalate, High-Quality DBP Supplier, Industrial Plasticizer DBP, Industrial Solvent DBP, Industrial-Grade DBP, Industrial-Grade Solvent DBP, Non-water-soluble DBP, Reliable DBP Distributor, Rubber Plasticizer Dibutyl Phthalate, Safe Handling Dibutyl Phthalate, solvent for adhesives