Description

Dodecylbenzenesulphonic Acid (DBSA) is a high-performance sulfonated surfactant widely used in industrial and commercial applications. Known for its excellent emulsifying, wetting, and dispersing properties, DBSA is a versatile chemical in detergent production, chemical synthesis, and as an intermediate for manufacturing sulfonates.

Applications of Dodecylbenzenesulphonic Acid (DBSA)

Detergents and Cleaning Products

- Purpose: A primary surfactant in cleaning formulations.

- Applications:

- Liquid dishwashing detergents and laundry detergents.

- Industrial and household cleaning products.

- Degreasers and heavy-duty cleaners.

Chemical Intermediate

- Purpose: A precursor for the production of sulfonates and other derivatives.

- Applications:

- Synthesis of linear alkylbenzene sulfonates (LAS), widely used in detergents.

- Manufacturing of other specialty chemicals.

Oil and Gas Industry

- Purpose: Enhances emulsification and dispersion in oilfield applications.

- Applications:

- Used in drilling fluids to improve stability.

- Assists in enhanced oil recovery processes.

Textile and Leather Processing

- Purpose: Acts as a wetting and leveling agent.

- Applications:

- Textile dyeing and finishing processes.

- Leather tanning and finishing for enhanced texture and uniformity.

Paints and Coatings

- Purpose: Improves the stability and texture of emulsions.

- Applications:

- Emulsifier in water-based paints and coatings.

- Enhances pigment dispersion for uniform finishes.

Agriculture

- Purpose: Improves the efficacy of agrochemical formulations.

- Applications:

- Surfactant in pesticides, herbicides, and fungicides.

- Enhances the spreading and sticking properties of sprays.

Water Treatment

- Purpose: Helps remove impurities and improve efficiency in water purification.

- Applications:

- Assists in cleaning membranes and other equipment in water treatment plants.

Adhesives and Sealants

- Purpose: Acts as an emulsifying and stabilizing agent.

- Applications:

- Used in the production of adhesives for improved texture and bonding properties.

Research and Development

- Purpose: A key reagent in industrial and academic research.

- Applications:

- Study of surfactant chemistry and emulsion technology.

- Development of advanced cleaning and emulsifying agents.

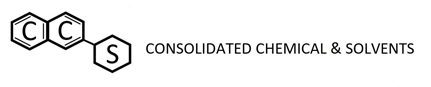

Storage:

- Temperature:

- Store at room temperature (15°C–25°C or 59°F–77°F).

- Avoid exposure to high heat or freezing conditions.

- Environment:

- Keep in a cool, dry, and well-ventilated area away from direct sunlight.

- Protect from moisture and incompatible substances, such as strong oxidizing agents or bases.

- Containers:

- Use tightly sealed, chemical-resistant containers (e.g., HDPE drums).

- Ensure containers are properly labeled to prevent accidental misuse.

- Segregation:

- Store separately from flammable or reactive chemicals.

Handling:

- Personal Protective Equipment (PPE):

- Gloves: Wear chemical-resistant gloves.

- Eye Protection: Use safety goggles or a face shield.

- Clothing: Wear a chemical-resistant apron or lab coat.

- Respiratory Protection: Use a respirator in poorly ventilated areas.

- Work Environment:

- Handle in a well-ventilated area or under a fume hood to minimize inhalation of vapors.

- Avoid eating, drinking, or smoking while handling the product.

- Hygiene Practices:

- Wash hands thoroughly after handling.

- Avoid direct contact with skin, eyes, and clothing.

- Spill Management:

- Use inert absorbent materials (e.g., sand or vermiculite) for spills.

- Avoid flushing into drains or waterways.

- Dispose of spill residues according to local regulations.

- Disposal:

- Follow federal, state, and local regulations for disposal of unused material or waste.