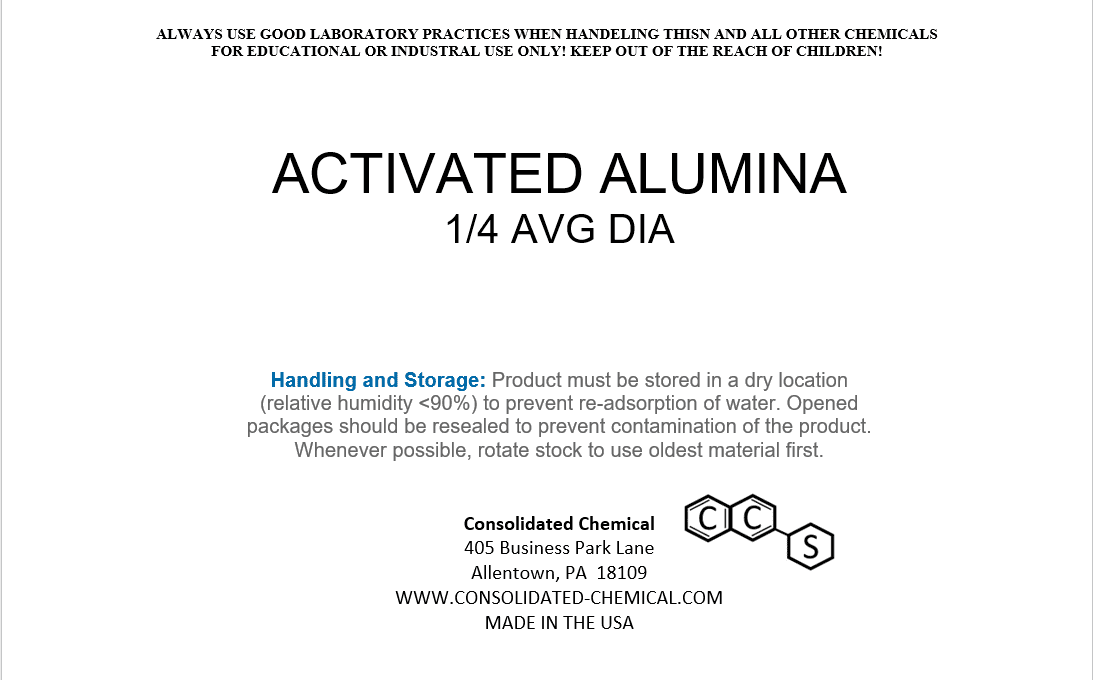

Activated Alumina Desiccant Pellets – 1/4 Inch Diameter

$14.99 – $29.99

General Information

- Product Name: Activated Alumina Desiccant Pellets

- Average Diameter: 1/4 inch (6–7 mm)

- Chemical Name: Aluminum Oxide

- CAS Number: 1344-28-1

- Molecular Formula: Al₂O₃

- Appearance: White, spherical pellets

- Odor: Odorless

Physical Properties

- Purity: ≥ 99% Aluminum Oxide

- Surface Area: 300–350 m²/g

- Pore Volume: 0.4–0.5 cm³/g

- Bulk Density: 0.72–0.75 g/cm³

- Crush Strength: ≥ 70 N/pellet

- Moisture Adsorption: 15–20% (depending on relative humidity)

- Regeneration Temperature: 200–300°C (392–572°F)

Chemical Properties

- pH Stability: Neutral (pH 7–8)

- Solubility: Insoluble in water and most solvents; resistant to acids and alkalis under normal conditions.

- Reactivity: Stable under normal storage and handling conditions.

Documents:

Description

Activated Alumina Desiccant Pellets are highly porous, high-capacity moisture absorbers engineered for efficient drying, purification, and filtration processes. Each pellet, with an average diameter of 1/4 inch, ensures superior airflow and adsorption performance, making it ideal for both small-scale and large-scale applications.

Applications of Activated Alumina Desiccant Pellets (1/4 Inch)

Air Drying and Moisture Control

- Removes moisture in compressed air dryers, dehumidifiers, and HVAC systems.

Water Treatment

- Removes fluoride, arsenic, and heavy metals in drinking water and wastewater treatment systems.

Gas Drying

- Dehydrates gases like natural gas, nitrogen, oxygen, and LPG to prevent freezing and corrosion.

Chemical and Petrochemical

- Used as a catalyst support and for solvent drying in chemical processes.

Desiccant Applications

- Protects moisture-sensitive products in packaging, shipping containers, and storage tanks.

Pharmaceuticals

- Moisture control in tablet production and chemical purification.

Electronics and Aerospace

- Prevents moisture damage in electronic components and cabin air systems.

Food and Beverage

- Extends shelf life as a packaging desiccant and purifies process gases.

Storage Instructions:

- Keep Dry: Store in a cool, dry place to prevent premature moisture absorption.

- Airtight Containers: Keep the pellets in sealed, airtight packaging (HDPE pails, bags, or drums) when not in use.

- Avoid Moisture Exposure: Do not expose the product to open air or humidity during storage, as Activated Alumina will absorb moisture from the environment.

- Temperature: Maintain a storage temperature between 5°C to 25°C (41°F to 77°F).

- Separation: Store away from water, acids, and strong alkaline substances to maintain chemical integrity.

Handling Instructions:

- Personal Protective Equipment (PPE):

- Wear safety goggles, gloves, and a dust mask when handling to prevent eye irritation and inhalation of dust.

- Minimize Dust:

- Handle gently to minimize the formation of dust, which can cause respiratory irritation.

- Avoid Water Contact:

- Do not add water directly to the pellets unless regenerating under controlled conditions.

- Safe Transfer:

- Use clean, dry tools or scoops to transfer the product into systems or equipment.

Regeneration:

- Procedure: Heat Activated Alumina pellets to 200°C–300°C (392°F–572°F) to remove absorbed moisture and restore adsorption capacity.

- Safety: Use appropriate equipment and ensure the process is carried out in a well-ventilated area or controlled environment.

Disposal of Activated:

- Dispose of used Activated Alumina in accordance with local, state, and federal regulations.

- Avoid releasing the material into drains, soil, or waterways.

Additional information

| Size | 250 Grams, 500 Grams, 1000 Grams |

|---|

Related products

-

Potassium Phosphate, Dibasic – Food Grade Additive

$14.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

1-Octanol (Alcohol C-8) Premium Aroma Fragrance Compound

$12.00 – $95.00 Select options This product has multiple variants. The options may be chosen on the product page -

Ferric Chloride Solution Liquid Etchant

$14.00 – $200.00 Select options This product has multiple variants. The options may be chosen on the product page -

Methylene Blue Stain/Dye High Purity, Poly Bottle, 10g-50g

$12.50 – $34.00 Select options This product has multiple variants. The options may be chosen on the product page

SKU: N/A

Categories: Industrial Chemical, Solvents (3), Water Treatment

Tags: 1/4 Inch Activated Alumina, activated alumina, Activated Alumina Adsorbent Media, Activated Alumina Bulk Supplier, Activated Alumina Desiccant, Activated Alumina Desiccant Supplier, Activated Alumina for Air Compressors, Activated Alumina for Air Drying, Activated Alumina for Chemical Processing, Activated Alumina for Dehumidifiers, Activated Alumina for Electronics, Activated Alumina for Gas Drying, Activated Alumina for HVAC Systems, Activated Alumina for Oil and Gas, Activated Alumina for Packaging, Activated Alumina for Petrochemical Industry, Activated Alumina for Pharmaceuticals, Activated Alumina for Sale, Activated Alumina for Storage Tanks, Activated Alumina for Wastewater Treatment, Activated Alumina for Water Filtration, Activated Alumina for Water Treatment, Activated Alumina Regeneration, Adsorbent Desiccant Pellets, Arsenic Removal Media, Buy Activated Alumina Online, Compressed Air Dryer Media, Desiccant Beads for Industrial Use, Fluoride Removal Media, High-Capacity Moisture Adsorbent, Industrial Desiccant Pellets, Moisture Absorbing Pellets, Moisture Control Pellets, Reusable Desiccant Pellets