Dodecylbenzenesulphonic Acid (DBSA) – High-Quality Surfactant

$14.99 – $34.00

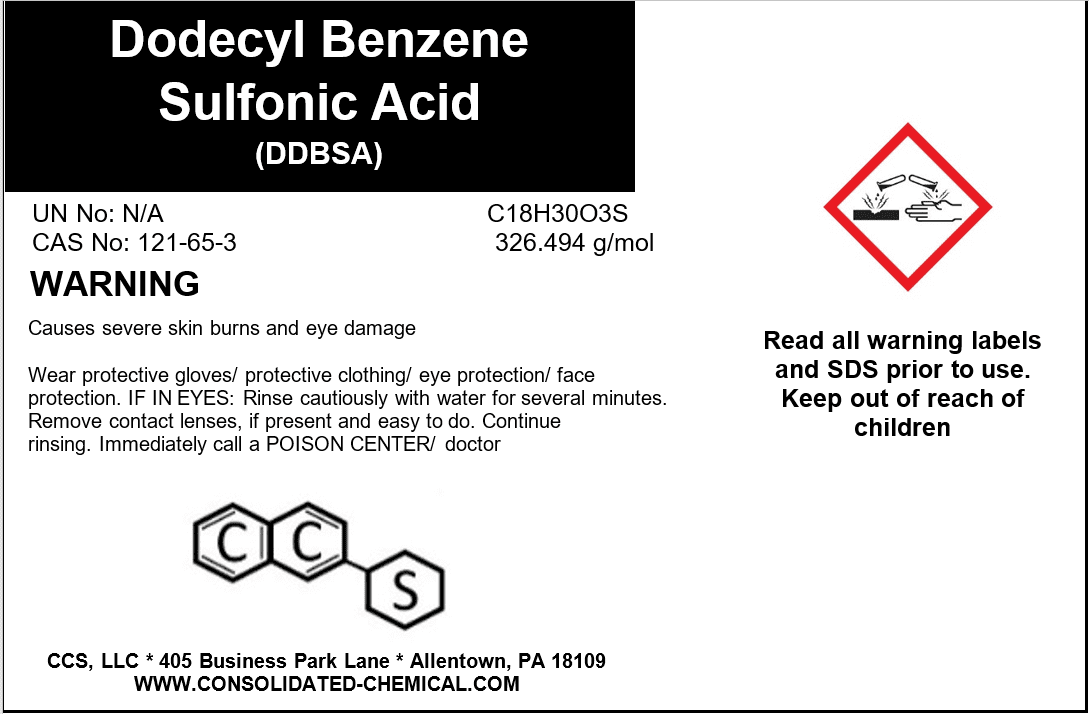

Chemical Identity:

- Chemical Name: Dodecylbenzenesulphonic Acid

- Chemical Formula: C18H30O3S

- CAS Number: 27176-87-0

- Molecular Weight: 326.49 g/mol

Physical and Chemical Properties:

- Appearance: Clear to pale yellow viscous liquid

- Odor: Mild, characteristic odor

- Purity: ≥ 96%

- Solubility:

- Soluble in water (forms emulsions)

- Soluble in alcohols and other organic solvents

- Density: ~1.06–1.08 g/cm³ at 25°C

- pH (1% aqueous solution): ~2.0 (acidic)

- Boiling Point: > 315°C (decomposes)

- Flash Point: > 150°C (closed cup)

Performance Characteristics:

- Surface Activity: High emulsifying, wetting, and dispersing capabilities.

- Stability: Stable under normal storage and handling conditions.

- Reactivity: Reacts with bases to form salts (e.g., sodium dodecylbenzenesulfonate).

Description

Dodecylbenzenesulphonic Acid (DBSA) is a high-performance sulfonated surfactant widely used in industrial and commercial applications. Known for its excellent emulsifying, wetting, and dispersing properties, DBSA is a versatile chemical in detergent production, chemical synthesis, and as an intermediate for manufacturing sulfonates.

Applications of Dodecylbenzenesulphonic Acid (DBSA)

Detergents and Cleaning Products

- Purpose: A primary surfactant in cleaning formulations.

- Applications:

- Liquid dishwashing detergents and laundry detergents.

- Industrial and household cleaning products.

- Degreasers and heavy-duty cleaners.

Chemical Intermediate

- Purpose: A precursor for the production of sulfonates and other derivatives.

- Applications:

- Synthesis of linear alkylbenzene sulfonates (LAS), widely used in detergents.

- Manufacturing of other specialty chemicals.

Oil and Gas Industry

- Purpose: Enhances emulsification and dispersion in oilfield applications.

- Applications:

- Used in drilling fluids to improve stability.

- Assists in enhanced oil recovery processes.

Textile and Leather Processing

- Purpose: Acts as a wetting and leveling agent.

- Applications:

- Textile dyeing and finishing processes.

- Leather tanning and finishing for enhanced texture and uniformity.

Paints and Coatings

- Purpose: Improves the stability and texture of emulsions.

- Applications:

- Emulsifier in water-based paints and coatings.

- Enhances pigment dispersion for uniform finishes.

Agriculture

- Purpose: Improves the efficacy of agrochemical formulations.

- Applications:

- Surfactant in pesticides, herbicides, and fungicides.

- Enhances the spreading and sticking properties of sprays.

Water Treatment

- Purpose: Helps remove impurities and improve efficiency in water purification.

- Applications:

- Assists in cleaning membranes and other equipment in water treatment plants.

Adhesives and Sealants

- Purpose: Acts as an emulsifying and stabilizing agent.

- Applications:

- Used in the production of adhesives for improved texture and bonding properties.

Research and Development

- Purpose: A key reagent in industrial and academic research.

- Applications:

- Study of surfactant chemistry and emulsion technology.

- Development of advanced cleaning and emulsifying agents.

Storage:

- Temperature:

- Store at room temperature (15°C–25°C or 59°F–77°F).

- Avoid exposure to high heat or freezing conditions.

- Environment:

- Keep in a cool, dry, and well-ventilated area away from direct sunlight.

- Protect from moisture and incompatible substances, such as strong oxidizing agents or bases.

- Containers:

- Use tightly sealed, chemical-resistant containers (e.g., HDPE drums).

- Ensure containers are properly labeled to prevent accidental misuse.

- Segregation:

- Store separately from flammable or reactive chemicals.

Handling:

- Personal Protective Equipment (PPE):

- Gloves: Wear chemical-resistant gloves.

- Eye Protection: Use safety goggles or a face shield.

- Clothing: Wear a chemical-resistant apron or lab coat.

- Respiratory Protection: Use a respirator in poorly ventilated areas.

- Work Environment:

- Handle in a well-ventilated area or under a fume hood to minimize inhalation of vapors.

- Avoid eating, drinking, or smoking while handling the product.

- Hygiene Practices:

- Wash hands thoroughly after handling.

- Avoid direct contact with skin, eyes, and clothing.

- Spill Management:

- Use inert absorbent materials (e.g., sand or vermiculite) for spills.

- Avoid flushing into drains or waterways.

- Dispose of spill residues according to local regulations.

- Disposal:

- Follow federal, state, and local regulations for disposal of unused material or waste.

Additional information

| Size | 100mL (3.3 Fl Oz), 250mL (8 Fl Oz), 500mL (16 Fl Oz), 1000mL (32 Fl Oz) |

|---|

Related products

-

Methylene Chloride (Dichloromethane)

$28.00 – $135.00 Select options This product has multiple variants. The options may be chosen on the product page -

Coumarin – High-Purity Aromatic Compound

$14.00 – $28.00 Select options This product has multiple variants. The options may be chosen on the product page -

Phenolphthalein Indicator w/ Dropper Bottle – Lab Grade

$9.99 – $34.99 Select options This product has multiple variants. The options may be chosen on the product page -

Copper (II) Carbonate – High Purity Solid

$14.99 – $45.00 Select options This product has multiple variants. The options may be chosen on the product page

SKU: N/A

Categories: Herbicide, Industrial Chemical, Pesticide, Surfactants (12), Uncategorized, Water Treatment

Tags: 27176-87-0, agricultural surfactant, Bulk DBSA Supplier, buy DBSA, buy Dodecylbenzenesulphonic Acid online, CAS 27176-87-0, Chemical Intermediate, cleaning agent surfactant, DBSA, DBSA acid, DBSA bulk packaging, DBSA bulk supplier, DBSA chemical, DBSA distributor, DBSA for adhesives, DBSA for agrochemicals, DBSA for Chemical Synthesis, DBSA for emulsions, DBSA for industrial applications, DBSA for Laundry Detergents, DBSA for oil and gas, DBSA for Paints and Coatings, DBSA for research, DBSA for soap production, DBSA for water treatment, DBSA price, DBSA supplier, DBSA wholesale, Detergent Raw Material, Dodecylbenzenesulfonic Acid, dodecylbenzenesulfonic acid supplier, Dodecylbenzenesulphonic Acid, dodecylbenzenesulphonic acid applications, dodecylbenzenesulphonic acid as acid catalyst, dodecylbenzenesulphonic acid best supplier, dodecylbenzenesulphonic acid biodegradability, dodecylbenzenesulphonic acid biodegradable, dodecylbenzenesulphonic acid boiling point, dodecylbenzenesulphonic acid bulk, dodecylbenzenesulphonic acid CAS 27176-87-0, dodecylbenzenesulphonic acid chemical market, dodecylbenzenesulphonic acid chemical properties, dodecylbenzenesulphonic acid chemical registration, dodecylbenzenesulphonic acid commercial supply, dodecylbenzenesulphonic acid competitive market analysis, dodecylbenzenesulphonic acid competitive pricing, dodecylbenzenesulphonic acid defoamer, dodecylbenzenesulphonic acid density, dodecylbenzenesulphonic acid detergent, dodecylbenzenesulphonic acid dispersant, dodecylbenzenesulphonic acid distributor, dodecylbenzenesulphonic acid eco-friendly, dodecylbenzenesulphonic acid emerging trends, dodecylbenzenesulphonic acid emulsifier, dodecylbenzenesulphonic acid environmental impact, dodecylbenzenesulphonic acid EU regulations, dodecylbenzenesulphonic acid FDA approved, dodecylbenzenesulphonic acid flash point, dodecylbenzenesulphonic acid flexible packaging, dodecylbenzenesulphonic acid foaming agent, dodecylbenzenesulphonic acid food grade, dodecylbenzenesulphonic acid future applications, dodecylbenzenesulphonic acid global demand, dodecylbenzenesulphonic acid global suppliers, dodecylbenzenesulphonic acid green chemistry, dodecylbenzenesulphonic acid hazard classification, dodecylbenzenesulphonic acid high purity, dodecylbenzenesulphonic acid household cleaning, dodecylbenzenesulphonic acid hydrolysis, dodecylbenzenesulphonic acid import/export, dodecylbenzenesulphonic acid in adhesives, dodecylbenzenesulphonic acid in agrochemicals, dodecylbenzenesulphonic acid in biodiesel production, dodecylbenzenesulphonic acid in body wash, dodecylbenzenesulphonic acid in car wash products, dodecylbenzenesulphonic acid in chemical reactions, dodecylbenzenesulphonic acid in coatings, dodecylbenzenesulphonic acid in cosmetics, dodecylbenzenesulphonic acid in degreasers, dodecylbenzenesulphonic acid in detergents, dodecylbenzenesulphonic acid in dishwashing liquid, dodecylbenzenesulphonic acid in disinfectants, dodecylbenzenesulphonic acid in drilling fluids, dodecylbenzenesulphonic acid in electroplating, dodecylbenzenesulphonic acid in emulsions, dodecylbenzenesulphonic acid in fertilizers, dodecylbenzenesulphonic acid in fuel additives, dodecylbenzenesulphonic acid in hair care, dodecylbenzenesulphonic acid in herbicides, dodecylbenzenesulphonic acid in household cleaners, dodecylbenzenesulphonic acid in industrial cleaners, dodecylbenzenesulphonic acid in laundry detergents, dodecylbenzenesulphonic acid in leather treatment, dodecylbenzenesulphonic acid in lubricant formulations, dodecylbenzenesulphonic acid in oilfield chemicals, dodecylbenzenesulphonic acid in organic synthesis, dodecylbenzenesulphonic acid in paints, dodecylbenzenesulphonic acid in paper industry, dodecylbenzenesulphonic acid in personal care, dodecylbenzenesulphonic acid in pesticides, dodecylbenzenesulphonic acid in polymers, dodecylbenzenesulphonic acid in rubber industry, dodecylbenzenesulphonic acid in sanitizers, dodecylbenzenesulphonic acid in shampoo, dodecylbenzenesulphonic acid in skin care, dodecylbenzenesulphonic acid in soap making, dodecylbenzenesulphonic acid in surface cleaners, dodecylbenzenesulphonic acid in textile processing, dodecylbenzenesulphonic acid in wastewater treatment, dodecylbenzenesulphonic acid industrial applications, dodecylbenzenesulphonic acid industrial grade, dodecylbenzenesulphonic acid industrial supply, dodecylbenzenesulphonic acid industry standards, dodecylbenzenesulphonic acid innovative applications, dodecylbenzenesulphonic acid international trade, dodecylbenzenesulphonic acid laboratory reagent, dodecylbenzenesulphonic acid manufacturer, dodecylbenzenesulphonic acid market trends, dodecylbenzenesulphonic acid melting point, dodecylbenzenesulphonic acid molecular formula, dodecylbenzenesulphonic acid molecular weight, dodecylbenzenesulphonic acid MSDS, dodecylbenzenesulphonic acid pH, dodecylbenzenesulphonic acid physical properties, dodecylbenzenesulphonic acid price, dodecylbenzenesulphonic acid procurement, dodecylbenzenesulphonic acid quality assurance, dodecylbenzenesulphonic acid raw material, dodecylbenzenesulphonic acid REACH compliant, dodecylbenzenesulphonic acid reactivity, dodecylbenzenesulphonic acid regulatory compliance, dodecylbenzenesulphonic acid regulatory updates, dodecylbenzenesulphonic acid research and development, dodecylbenzenesulphonic acid research chemical, dodecylbenzenesulphonic acid safety data sheet, dodecylbenzenesulphonic acid safety guidelines, dodecylbenzenesulphonic acid safety handling, dodecylbenzenesulphonic acid solubility, dodecylbenzenesulphonic acid specialty chemicals, dodecylbenzenesulphonic acid stability, dodecylbenzenesulphonic acid storage conditions, dodecylbenzenesulphonic acid structure, dodecylbenzenesulphonic acid supply chain, dodecylbenzenesulphonic acid surfactant, dodecylbenzenesulphonic acid sustainable chemistry, dodecylbenzenesulphonic acid synthesis, dodecylbenzenesulphonic acid technical grade, dodecylbenzenesulphonic acid transportation, dodecylbenzenesulphonic acid US regulations, dodecylbenzenesulphonic acid verified supplier, dodecylbenzenesulphonic acid wetting agent, dodecylbenzenesulphonic acid worldwide shipping, emulsifier for detergents, high-purity DBSA, Industrial Surfactant, Industrial-Grade DBSA, leather processing chemical, liquid detergent ingredient, pesticide emulsifier, premium-quality DBSA, sulfonic acid, surfactant for cleaning products, textile wetting agent, versatile industrial surfactant