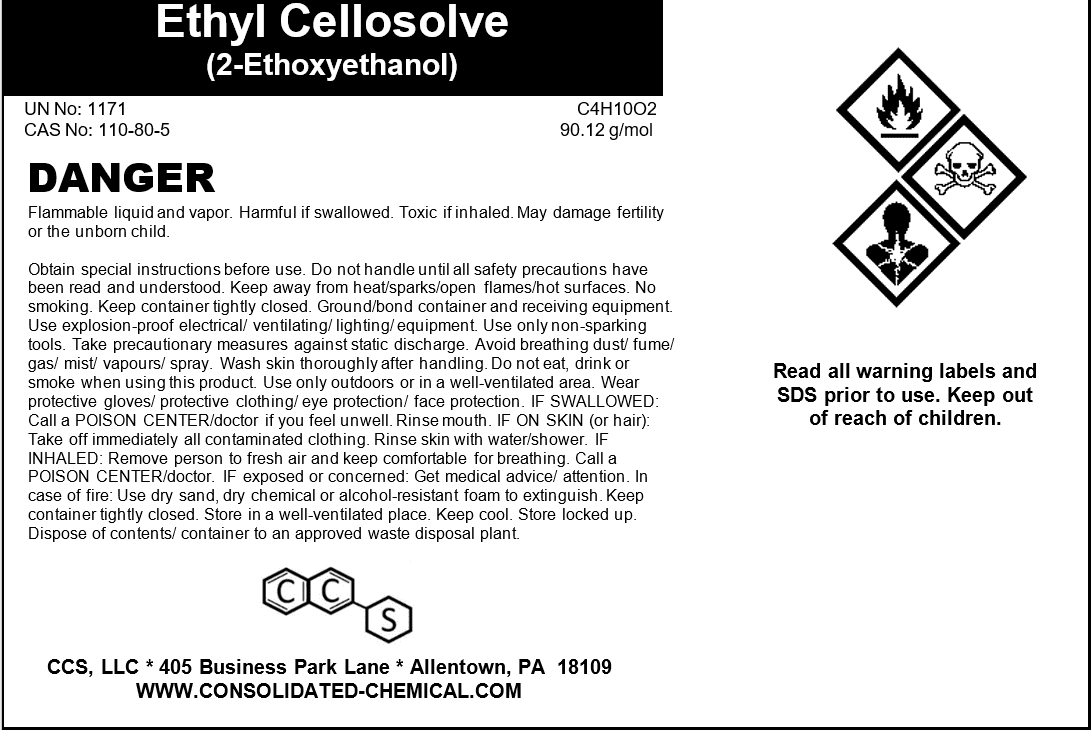

Ethyl Cellosolve (2-Ethoxyethanol) – Reagent Grade

$22.00 – $79.99

Chemical Identity:

- Chemical Name: Ethyl Cellosolve

- Synonyms: 2-Ethoxyethanol, Glycol Ether EE, Monoethyl Glycol Ether

- Chemical Formula: C4H10O2

- CAS Number: 110-80-5

- Molecular Weight: 90.12 g/mol

Physical and Chemical Properties:

- Appearance: Clear, colorless liquid

- Odor: Mild, ether-like odor

- Purity: ≥ 99% (Reagent Grade)

- Boiling Point: 135°C (275°F)

- Melting Point: -70°C (-94°F)

- Density: ~0.93 g/cm³ at 20°C

- Flash Point: 49°C (120°F) (closed cup)

- Solubility:

- Completely miscible with water

- Soluble in alcohols, ethers, and other organic solvents

- Vapor Pressure: ~3.5 mmHg at 20°C

- Refractive Index: 1.403–1.405 at 20°C

Performance Characteristics:

- High Solvency: Excellent solvent for resins, oils, and waxes.

- Versatility: Used in a wide range of industrial and laboratory applications.

- Reactivity: Can undergo etherification and esterification.

Documents :

Description

Ethyl Cellosolve, also known as 2-Ethoxyethanol, is a high-purity, versatile solvent widely used in industrial, laboratory, and chemical processes. Known for its excellent solvency and low viscosity, it is ideal for use in coatings, cleaning solutions, and as a solvent in various chemical reactions. Packaged securely in leak-proof containers, this product ensures reliability and safety for demanding applications.

Applications for Ethyl Cellosolve (2-Ethoxyethanol)

Paints, Coatings, and Varnishes

- Solvent for Resins: Dissolves a wide range of resins, making it an essential ingredient in paints, coatings, and varnishes.

- Coating Formulations: Improves the spreadability and penetration of coatings, ensuring a smooth and even finish.

- Viscosity Control: Used as a thinner in coating formulations to adjust viscosity.

Cleaning and Degreasing

- Industrial Cleaners: Used in cleaning solutions for removing oils, greases, and dirt from surfaces and equipment.

- Electronic Component Cleaning: Ideal for cleaning delicate electronic parts and circuit boards without causing damage.

- Degreasing Solvent: Effectively breaks down and removes stubborn grease and oil residues.

Chemical Synthesis

- Intermediate for Esters and Ethers: Acts as a precursor in the production of esters and ethers used in specialty chemicals.

- Plasticizer Production: A key ingredient in the synthesis of plasticizers for flexible plastics.

- Chemical Reactions: Used in laboratory and industrial settings for organic synthesis and reaction optimization.

Textile and Leather Industry

- Dye Solvent: Enhances the penetration and fixation of dyes on textiles and leather.

- Finishing Agent: Used in the treatment and finishing of textiles to improve appearance and durability.

Pharmaceuticals

- Extraction Solvent: Utilized in the extraction of certain active pharmaceutical ingredients (APIs).

- Excipient in Formulations: Used in specific drug formulations for solubilizing active components.

Printing Industry

- Ink Solvent: Dissolves and stabilizes inks used in printing processes, ensuring sharp and consistent print quality.

- Adhesive Formulations: Used in adhesive products to improve flow and adhesion properties.

Agricultural Industry

- Pesticide Carrier: Enhances the delivery and dispersion of pesticides on crops.

- Adjuvant: Improves the effectiveness of herbicides and fungicides by promoting better penetration into plant tissues.

Automotive and Aerospace

- Component Cleaner: Used to clean automotive and aerospace parts during manufacturing and maintenance.

- Coating Additive: Improves the performance of protective coatings for vehicles and aircraft.

Plastics and Polymers

- Polymerization Solvent: Used in the production and processing of polymers and plastics.

- Flexible Films: Aids in the production of flexible films and coatings for packaging.

Environmental Applications

- Soil and Water Remediation: Acts as a solvent in cleaning and remediation processes for polluted environments.

- Oil Spill Management: Aids in the dispersion and breakdown of oil spills in aquatic environments.

Laboratory and Research

- Solvent for Analysis: Used in chromatography and other analytical techniques.

- Sample Preparation: Helps in dissolving or stabilizing chemical samples for laboratory studies.

Storage Guidelines

- Temperature Control:

- Store in a cool, dry, and well-ventilated area.

- Maintain storage temperatures between 15°C and 30°C (59°F to 86°F) to prevent degradation.

- Light and Heat Protection:

- Keep away from direct sunlight, heat sources, and open flames.

- Avoid storing near oxidizing agents or acids, as Ethyl Cellosolve can react with these substances.

- Container Requirements:

- Use tightly sealed, corrosion-resistant containers made of stainless steel, aluminum, or high-density polyethylene (HDPE).

- Ensure containers are labeled correctly with hazard and identification information.

- Ventilation:

- Store in a well-ventilated space to prevent the buildup of vapors, which are flammable and harmful if inhaled.

- Fire Safety:

- Store away from ignition sources.

- Use approved flammable liquid storage cabinets if required.

- Shelf Life:

- Typically stable for up to 2 years under recommended storage conditions.

Handling Guidelines

- Personal Protective Equipment (PPE):

- Gloves: Wear chemical-resistant gloves (e.g., nitrile or neoprene).

- Eye Protection: Use safety goggles or a face shield to protect against splashes.

- Clothing: Wear a lab coat or chemical-resistant apron.

- Respiratory Protection: Use a properly fitted respirator if working in poorly ventilated areas.

- Safe Handling Practices:

- Always work in a well-ventilated area or under a fume hood to minimize vapor inhalation.

- Avoid direct contact with skin, eyes, or clothing.

- Use non-sparking tools and grounded equipment to handle the liquid safely.

- Spill Management:

- In case of spills, absorb with inert material (e.g., sand or vermiculite).

- Avoid letting the spill enter drains or waterways. Dispose of according to local regulations.

- Mixing and Dilution:

- When mixing Ethyl Cellosolve with other chemicals, add it slowly and with constant stirring to avoid reactions.

- Never mix with strong oxidizing agents or acids.

Warning

Exposure can cause irritation of the eyes, nose, throat and lungs with cough and/or shortness of breath.

Flammable/Combustible liquid and vapours.

California Prop. 65 Components

This product contains chemicals known to State of California to cause birth defects, or any other reproductive harm.

Additional information

| Size | 500mL (16 Fl Oz), 1000mL (32 Fl Oz), 1 Gallon (128 Fl Oz) |

|---|

Related products

-

1-Octanol (Alcohol C-8) Premium Aroma Fragrance Compound

$12.00 – $95.00 Select options This product has multiple variants. The options may be chosen on the product page -

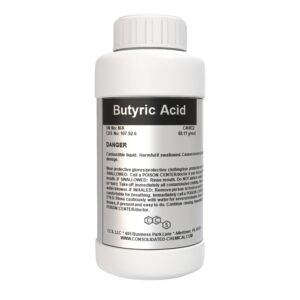

Butyric Acid – FCC Grade

$11.00 – $69.99 Select options This product has multiple variants. The options may be chosen on the product page -

Triethyl Citrate HP Aroma/Flavor/Fragrance Compound

$12.00 – $150.00 Select options This product has multiple variants. The options may be chosen on the product page -

Ethylene Glycol – Premium Industrial-Grade

$19.99 – $27.00 Select options This product has multiple variants. The options may be chosen on the product page

Reviews

There are no reviews yet.