Furfuryl Alcohol – High-Purity Solvent

$14.00 – $39.99

Chemical Identity

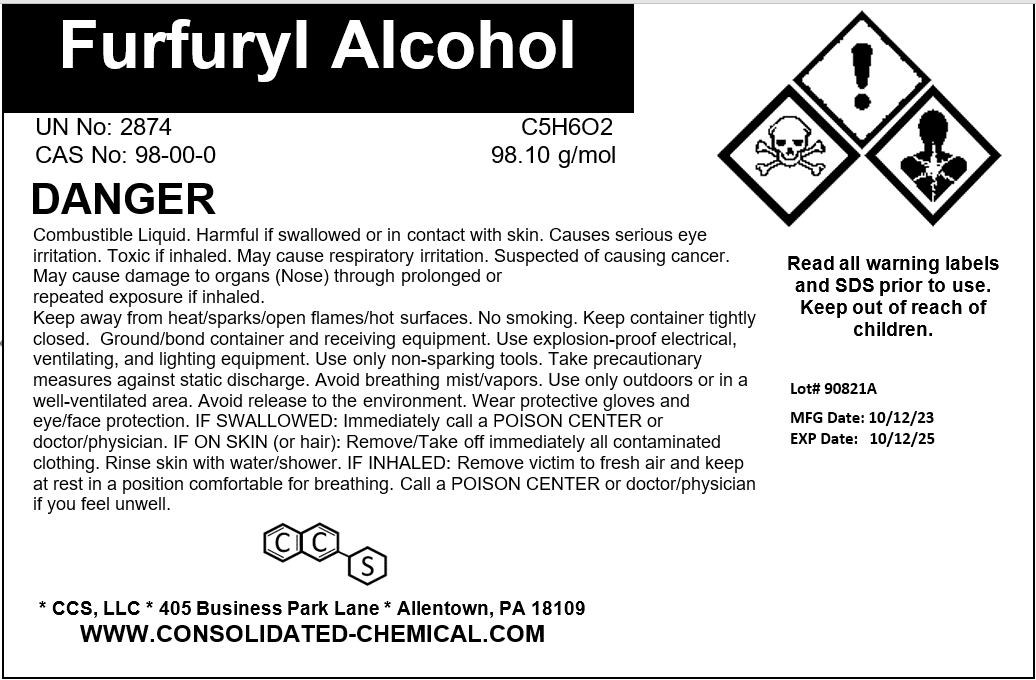

- Chemical Name: Furfuryl Alcohol

- Other Names: 2-Furylmethanol, Furfural Alcohol

- Chemical Formula: C₅H₆O₂

- Molecular Weight: 98.10 g/mol

- CAS Number: 98-00-0

- EC Number: 202-626-1

Physical Properties

- Appearance: Clear to pale yellow liquid (may darken with time or exposure to light and air)

- Odor: Mild, sweet odor resembling burnt sugar

- Density: ~1.13 g/cm³ at 20°C

- Boiling Point: ~170°C (338°F)

- Melting Point: -29°C (-20°F)

- Flash Point: ~78°C (172°F) (closed cup)

- Vapor Pressure: 0.29 mmHg at 25°C

- Refractive Index: 1.485 at 20°C

- Solubility in Water: Miscible

- Viscosity: ~5.8 mPa·s at 25°C

Description

Furfuryl Alcohol is a high-purity, multi-functional solvent widely used in industrial and laboratory applications. With its unique reactivity and polymerization properties, it plays a crucial role in the production of resins, foundry sand binders, and corrosion-resistant coatings. Furfuryl Alcohol is also a preferred intermediate in the synthesis of polymers and other specialty chemicals.

Applications for Furfuryl Alcohol:

Industrial Applications

- Resin Manufacturing:

Furfuryl Alcohol is a critical raw material in the production of furan resins and phenolic resins, widely used in coatings, adhesives, and composite materials. - Foundry Sand Binders:

Acts as a binder in foundry applications for creating durable and heat-resistant sand molds and cores, essential in metal casting processes. - Coatings and Adhesives:

Enhances corrosion resistance and durability in specialty coatings and adhesives used in industrial and construction environments.

Chemical Synthesis

- Intermediate for Specialty Chemicals:

Used in the production of solvents, plasticizers, and other specialty chemicals. - Polymer Synthesis:

Serves as a reactive intermediate for synthesizing high-performance polymers and thermosetting plastics.

Environmental and Construction Applications

- Corrosion-Resistant Materials:

Used in the production of linings and coatings that protect against chemical and environmental corrosion, especially in pipelines, tanks, and industrial equipment. - Grouting and Cement Additives:

Improves strength, durability, and chemical resistance in grouts and cement formulations.

Laboratory and Research Applications

- Solvent in Organic Reactions:Acts as a solvent and reactant in various organic synthesis applications, especially for furan derivatives.

Textile Industry

- Dyeing and Finishing:Used as a solvent and processing agent in textile dyeing and finishing applications.

Energy and Fuel Applications

- Renewable Fuels:Serves as a potential feed stock for producing bio-based chemicals and fuels due to its origin from renewable agricultural byproducts.

Storage Recommendations

- Storage Conditions:

- Store in a cool, dry, and well-ventilated area.

- Keep away from heat, open flames, sparks, and other ignition sources.

- Avoid exposure to direct sunlight or temperatures above 30°C (86°F) to maintain stability.

- Container Requirements:

- Use tightly sealed, chemical-resistant containers to prevent evaporation or contamination.

- Ensure containers are labeled with the product name, CAS number, and hazard warnings.

- Segregation:

- Store separately from oxidizing agents, acids, and bases to prevent hazardous reactions.

- Keep away from incompatible materials such as strong alkalis and nitrates.

Handling Guidelines

- Personal Protective Equipment (PPE):

- Gloves: Wear chemical-resistant gloves (e.g., nitrile or butyl rubber) to avoid skin contact.

- Eye Protection: Use safety goggles or a face shield to prevent splashes.

- Clothing: Wear chemical-resistant clothing or a lab coat to protect skin.

- Respiratory Protection: Use an approved respirator with organic vapor cartridges in poorly ventilated areas.

- Work Area:

- Handle in a well-ventilated area or under a fume hood to minimize vapor inhalation.

- Use spark-proof tools and explosion-proof equipment when working with Furfuryl Alcohol.

- Safe Handling Practices:

- Avoid inhalation of vapors, ingestion, or direct contact with skin and eyes.

- Do not eat, drink, or smoke while handling the product.

- Wash hands thoroughly after handling.

Additional information

| Size | 100mL (3.3 Fl Oz), 250mL (8 Fl Oz), 500mL (16 Fl Oz), 1000mL (32 Fl Oz) |

|---|

Related products

-

Silver Nitrate – Premium High-Purity Grade

$19.99 – $220.00 Select options This product has multiple variants. The options may be chosen on the product page -

Geraniol | High-Purity Fragrance/Aroma Compound

$9.99 – $800.00 Select options This product has multiple variants. The options may be chosen on the product page -

Ferrofluid Magnetic Liquid

$12.00 – $260.00 Select options This product has multiple variants. The options may be chosen on the product page -

Cinnamic Acid – High Purity | Premium Quality

$14.99 – $48.00 Select options This product has multiple variants. The options may be chosen on the product page

SKU: N/A

Categories: Industrial Chemical, Solvents (3)

Tags: buy furfuryl alcohol, CAS 98-00-0, Chemical Intermediate, Chemical-grade Furfuryl Alcohol, Foundry sand binder, Furfuryl Alcohol, furfuryl alcohol adhesives, furfuryl alcohol alternative solvents, furfuryl alcohol applications, furfuryl alcohol binder, furfuryl alcohol bio-based chemicals, furfuryl alcohol bio-based solvent, furfuryl alcohol boiling point, furfuryl alcohol bulk, furfuryl alcohol CAS 98-00-0, furfuryl alcohol chemical formula, furfuryl alcohol chemical industry trends, furfuryl alcohol chemical intermediate, furfuryl alcohol corrosion inhibitor, furfuryl alcohol demand, furfuryl alcohol density, furfuryl alcohol distributor, furfuryl alcohol environmental impact, furfuryl alcohol export, furfuryl alcohol flash point, furfuryl alcohol food grade, Furfuryl alcohol for coatings, furfuryl alcohol for coatings and adhesives, Furfuryl alcohol for corrosion-resistant coatings, Furfuryl alcohol for foundry use, furfuryl alcohol for polymer industry, Furfuryl alcohol for resins, furfuryl alcohol for sale, furfuryl alcohol foundry applications, furfuryl alcohol foundry resins, furfuryl alcohol fuel additives, furfuryl alcohol furan resins, furfuryl alcohol global market, furfuryl alcohol global suppliers, furfuryl alcohol green solvent, furfuryl alcohol handling, furfuryl alcohol hazards, furfuryl alcohol high purity, furfuryl alcohol import, furfuryl alcohol in agriculture, furfuryl alcohol in coatings, furfuryl alcohol in fragrances, furfuryl alcohol in pesticides, furfuryl alcohol in pharmaceuticals, furfuryl alcohol in plastics, furfuryl alcohol in rubber industry, furfuryl alcohol in textiles, furfuryl alcohol industrial applications, furfuryl alcohol industrial grade, furfuryl alcohol lab reagent, furfuryl alcohol logistics, furfuryl alcohol manufacturer, furfuryl alcohol metal casting, furfuryl alcohol molecular weight, furfuryl alcohol monomer, furfuryl alcohol MSDS, furfuryl alcohol near me, furfuryl alcohol organic synthesis, furfuryl alcohol packaging, furfuryl alcohol pharma grade, furfuryl alcohol phenolic resins, furfuryl alcohol polymer precursor, furfuryl alcohol price, furfuryl alcohol production process, furfuryl alcohol properties, furfuryl alcohol reactive diluent, furfuryl alcohol renewable chemicals, furfuryl alcohol resin production, furfuryl alcohol safety data sheet, furfuryl alcohol solubility, furfuryl alcohol solvent, furfuryl alcohol specialty chemicals, furfuryl alcohol storage, furfuryl alcohol structure, furfuryl alcohol supplier, furfuryl alcohol supply chain, furfuryl alcohol synthesis, furfuryl alcohol technical grade, furfuryl alcohol toxicity, furfuryl alcohol trade, furfuryl alcohol uses, furfuryl alcohol viscosity, furfuryl alcohol wholesale, furfuryl alcohol wood preservation, High Purity Solvent, High-Performance Solvent, Industrial-grade Furfuryl Alcohol, Laboratory Solvent, Organic chemical intermediate, Polymer synthesis solvent, Reactive polymer precursor, Resin manufacturing chemical, Solvent for industrial applications, Solvent for polymers