N-Butyl Acetate – High-Purity Industrial Solvent & Coating Additive

$14.99 – $79.99

General Information

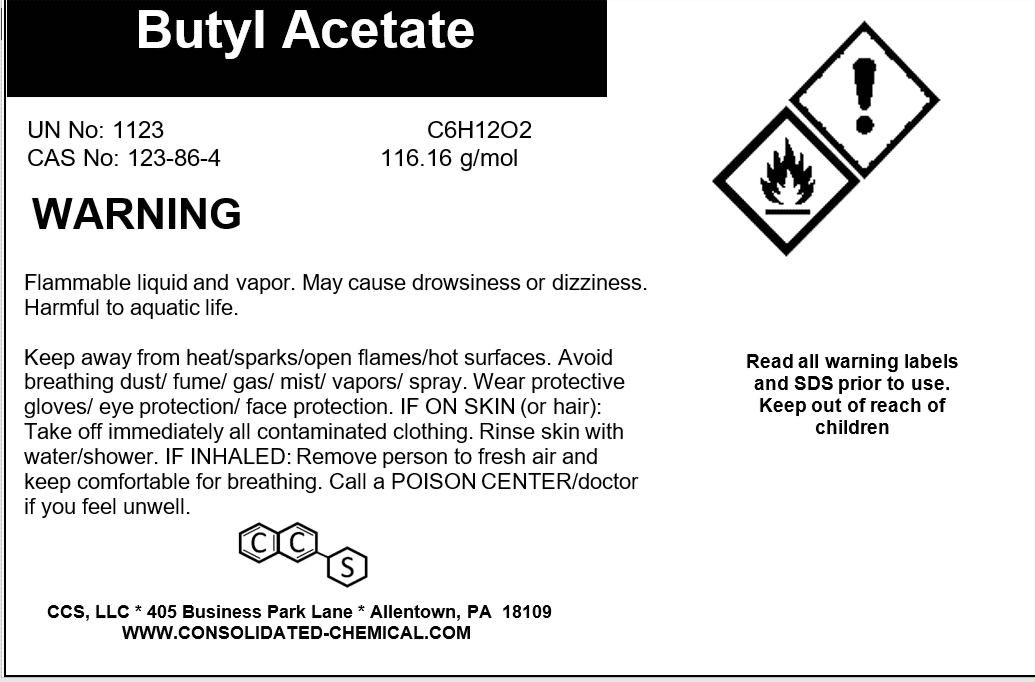

- Chemical Name: N-Butyl Acetate

- Synonyms: Butyl Ethanoate, Acetic Acid Butyl Ester

- CAS Number: 123-86-4

- EC Number: 204-658-1

- Molecular Formula: C₆H₁₂O₂

- Molecular Weight: 116.16 g/mol

- Source: Synthetic

Physical Properties

- Appearance: Clear, colorless liquid

- Odor: Fruity, sweet aroma

- Purity: ≥ 99%

- Density: ~0.88 g/cm³ at 20°C

- Boiling Point: ~126°C

- Flash Point: 27°C (80.6°F, Closed Cup)

- Refractive Index: 1.394–1.397 at 20°C

- Vapor Pressure: ~10.5 mmHg at 20°C

- Evaporation Rate: Moderate, compared to butyl acetate as standard

- Solubility:

- Slightly soluble in water (5.4 g/L at 20°C)

- Fully miscible with alcohols, ketones, and ethers

Chemical Properties

- Stability: Stable under normal storage and handling conditions.

- Reactivity: Reacts with strong oxidizing agents, acids, and alkalis.

- Autoignition Temperature: ~420°C

Documents :

Description

Our N-Butyl Acetate is a high-purity solvent widely used across industries for its excellent solvency, moderate evaporation rate, and compatibility with a variety of resins and polymers. Its pleasant fruity odor makes it a preferred choice in coatings, adhesives, and cleaning formulations. With its versatile performance, N-Butyl Acetate ensures optimal results in industrial and commercial applications.

Applications of N-Butyl Acetate – High-Purity Solvent

Paints, Coatings & Adhesives Industry

- Industrial Solvent: Used in lacquers, varnishes, enamels, and automotive coatings.

- Paint Thinner & Diluent: Enhances solubility and flow properties of coatings.

- Adhesive Formulations: Improves adhesion strength and drying efficiency.

Printing & Inks Industry

- Flexographic & Gravure Inks: Provides fast drying and excellent solubility.

- Screen Printing & Offset Inks: Used in high-performance printing applications.

- Packaging & Label Printing: Helps in formulating quick-drying printing inks.

Chemical & Pharmaceutical Industry

- Intermediate in Chemical Synthesis: Used in organic reactions and esterification.

- Pharmaceutical Excipient: Functions as a carrier solvent in drug formulations.

- Laboratory & Analytical Applications: Serves as a reference solvent in chromatography.

Personal Care & Fragrance Industry

- Perfumes & Fragrances: Used as a carrier solvent in cosmetic formulations.

- Nail Polish & Removers: Enhances spreadability and evaporation rate.

- Skincare & Cosmetics: Found in various personal care formulations.

Cleaning & Industrial Degreasing

- Industrial Cleaning Agents: Used in metal cleaning, degreasing, and solvent blends.

- Electronic Component Cleaning: Removes contaminants from circuit boards and parts.

- Surface Preparation: Helps in removing residues before coating applications.

Storage

- Store in a cool, dry, and well-ventilated area.

- Keep away from heat sources, sparks, open flames, and strong oxidizing agents.

- Use approved containers to prevent contamination.

Handling

- Use protective gloves, safety goggles, and proper ventilation when handling.

- Avoid prolonged skin contact and inhalation of vapors.

- Use in a well-ventilated environment or with fume extraction systems.

Safety

- Flammable liquid; handle with caution.

- Avoid inhalation and ingestion; may cause dizziness and respiratory irritation.

- Follow OSHA, EPA, and industrial safety regulations.

- Material Safety Data Sheet (MSDS) available upon request.

Additional information

| Size | 100mL (3.3 Fl Oz), 250mL (8 Fl Oz), 500mL (16 Fl Oz), 1000mL (32 Fl Oz), 1 Gallon (128 Fl Oz) |

|---|

Related products

-

Tetrahydrofuran (THF) – Premium High Purity Solvent

$18.00 – $600.00 Select options This product has multiple variants. The options may be chosen on the product page -

Silver Nitrate – Premium High-Purity Grade

$19.99 – $220.00 Select options This product has multiple variants. The options may be chosen on the product page -

X-100 Nonionic Surfactant – High Performance

$15.99 – $99.99 Select options This product has multiple variants. The options may be chosen on the product page -

Potassium Phosphate, Dibasic – Food Grade Additive

$14.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page

SKU: N/A

Categories: Absorbant, Fragrance Chemical, Fragrances & Aromas (15), Industrial Chemical, Research, Solvents (3)

Tags: Acetic Acid Butyl Ester, Butyl Acetate, butyl acetate bulk supplier, butyl acetate chemical, butyl acetate chemical synthesis, butyl acetate distributor, butyl acetate eco-friendly solvent, butyl acetate fast-evaporating solvent, butyl acetate for adhesive formulations, butyl acetate for adhesives, butyl acetate for advanced materials, butyl acetate for aerospace coatings, butyl acetate for aerospace materials, butyl acetate for agrochemical formulations, butyl acetate for alternative solvents, butyl acetate for architectural paints, butyl acetate for automotive coatings, butyl acetate for battery production, butyl acetate for binder formulations, butyl acetate for bio-based coatings, butyl acetate for biochemical research, butyl acetate for biodegradable coatings, butyl acetate for biofuel production, butyl acetate for cement additives, butyl acetate for chemical intermediates, butyl acetate for chemical processing, butyl acetate for chemical refinement, butyl acetate for chemical synthesis, butyl acetate for chromatography, butyl acetate for cleaning, butyl acetate for coatings, butyl acetate for construction chemicals, butyl acetate for construction materials, butyl acetate for controlled evaporation rate, butyl acetate for cosmetic formulations, butyl acetate for cosmetics, butyl acetate for custom chemical formulations, butyl acetate for decorative coatings, butyl acetate for degreasing, butyl acetate for drilling fluids, butyl acetate for eco-friendly manufacturing, butyl acetate for electrochemical applications, butyl acetate for electronic component cleaning, butyl acetate for electroplating, butyl acetate for emission-free coatings, butyl acetate for energy storage applications, butyl acetate for energy-efficient coatings, butyl acetate for environmental coatings, butyl acetate for environmental science, butyl acetate for environmentally friendly coatings, butyl acetate for fine chemical production, butyl acetate for flexible packaging, butyl acetate for flexographic inks, butyl acetate for food contact coatings, butyl acetate for food packaging inks, butyl acetate for fragrance formulations, butyl acetate for fuel additives, butyl acetate for functional coatings, butyl acetate for furniture finishes, butyl acetate for general-purpose cleaning, butyl acetate for gravure inks, butyl acetate for green chemistry applications, butyl acetate for heat-resistant coatings, butyl acetate for high-gloss coatings, butyl acetate for high-performance adhesives, butyl acetate for high-performance coatings, butyl acetate for high-performance composites, butyl acetate for high-purity applications, butyl acetate for high-temperature applications, butyl acetate for household products, butyl acetate for hydrocarbon solvents, butyl acetate for hydrogen fuel cells, butyl acetate for industrial applications, butyl acetate for industrial cleaning, butyl acetate for industrial degreasing, butyl acetate for industrial filtration, butyl acetate for industrial formulations, butyl acetate for industrial processing, butyl acetate for industrial sealants, butyl acetate for ink dilution, butyl acetate for ink manufacturing, butyl acetate for inkjet formulations, butyl acetate for inkjet printers, butyl acetate for innovative materials, butyl acetate for laboratory use, butyl acetate for low-VOC formulations, butyl acetate for marine coatings, butyl acetate for marine varnishes, butyl acetate for medical coatings, butyl acetate for medical research, butyl acetate for metal coatings, butyl acetate for metal protection, butyl acetate for nail polish, butyl acetate for nanotechnology, butyl acetate for non-polar solvent applications, butyl acetate for oil-based coatings, butyl acetate for oilfield chemicals, butyl acetate for organic synthesis, butyl acetate for packaging materials, butyl acetate for paint thinner, butyl acetate for paints, butyl acetate for perfumes, butyl acetate for personal care, butyl acetate for personal care formulations, butyl acetate for petroleum refining, butyl acetate for pharmaceutical excipients, butyl acetate for pharmaceuticals, butyl acetate for plastic coatings, butyl acetate for polymer dispersions, butyl acetate for polymer production, butyl acetate for printing industry, butyl acetate for printing press applications, butyl acetate for protective coatings, butyl acetate for renewable resources, butyl acetate for resin production, butyl acetate for rubber processing, butyl acetate for semiconductor manufacturing, butyl acetate for smart coatings, butyl acetate for solvent blends, butyl acetate for solvent extraction, butyl acetate for solvent recovery, butyl acetate for solvent-based coatings, butyl acetate for solvent-based formulations, butyl acetate for specialty coatings, butyl acetate for stain removers, butyl acetate for surface modification, butyl acetate for surfactants, butyl acetate for sustainable chemical solutions, butyl acetate for sustainable energy solutions, butyl acetate for synthetic elastomers, butyl acetate for synthetic fibers, butyl acetate for synthetic lubricants, butyl acetate for synthetic resins, butyl acetate for textile dyeing, butyl acetate for textiles, butyl acetate for transport coatings, butyl acetate for university laboratories, butyl acetate for UV-curable inks, butyl acetate for varnish formulations, butyl acetate for water treatment chemicals, butyl acetate for water-based coatings, butyl acetate for waterborne coatings, butyl acetate for wood coatings, butyl acetate for wood lacquers, butyl acetate high purity, butyl acetate industrial grade, butyl acetate manufacturer, butyl acetate MSDS, butyl acetate online supplier, butyl acetate price, butyl acetate REACH compliant, butyl acetate RoHS compliant, butyl acetate safe handling, butyl acetate safety data sheet, butyl acetate shipping regulations, butyl acetate solvent, butyl acetate storage guidelines, butyl acetate wholesale, buy butyl acetate, Buy Industrial Solvents, Buy N-Butyl Acetate Online, Fruity aroma solvent, High-Purity N-Butyl Acetate, High-Quality Butyl Acetate, Industrial Solvent, N-Butyl Acetate, N-Butyl Acetate Bulk Supplier, N-Butyl Acetate Distributor, N-Butyl Acetate for Automotive Paints, N-Butyl Acetate for Chemical Synthesis, N-Butyl Acetate for Cleaning Solutions, N-Butyl Acetate for Coatings, N-Butyl Acetate for Degreasing, N-Butyl Acetate for Fragrance Formulations, N-Butyl Acetate for Industrial Cleaning, N-Butyl Acetate for Lacquers, N-Butyl Acetate for Manufacturing, N-Butyl Acetate for Paints, N-Butyl Acetate for Printing Applications, N-Butyl Acetate for Printing Inks, N-Butyl Acetate for Sale, N-Butyl Acetate for Sealants, n-butyl acetate solvent, N-Butyl Acetate Technical Grade, N-Butyl Acetate Wholesale, Reliable Solvent for Coatings, solvent for adhesives, Solvent for Surface Preparation, Versatile Industrial Solvent