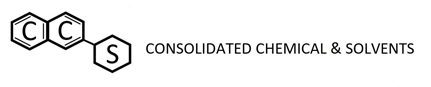

Methyl Ethyl Ketone (MEK) – High-Purity Solvent

$14.99 – $34.00

Chemical Identity

- Chemical Name: Methyl Ethyl Ketone (MEK)

- IUPAC Name: Butan-2-one

- CAS Number: 78-93-3

- Molecular Formula: C₄H₈O

- Molecular Weight: 72.11 g/mol

- EINECS Number: 201-159-0

Physical Properties

- Appearance: Clear, colorless liquid

- Odor: Sweet, pungent odor similar to acetone

- Boiling Point: 79.6°C (175.3°F)

- Melting Point: -86°C (-123°F)

- Density: 0.805 g/cm³ at 20°C

- Refractive Index: 1.378 at 20°C

- Flash Point: 11°C (52°F), closed cup

- Vapor Pressure: 88 mmHg at 20°C

- Solubility:

- Water: Miscible

- Organic Solvents: Miscible with most organic solvents like ethanol, acetone, ether, and chloroform

Chemical Properties

- Purity: ≥ 99% (typically for industrial-grade)

- Stability: Stable under normal conditions; avoid contact with strong oxidizing agents, acids, and bases.

- Reactivity: Reacts with strong acids, bases, and oxidizers.

- Functional Group: Ketone (C=O)

Description

Methyl Ethyl Ketone (MEK) is a highly versatile, fast-evaporating solvent widely used in various industrial, chemical, and laboratory applications. Known for its excellent solvency power, MEK effectively dissolves a wide range of resins, polymers, and other substances, making it a key ingredient in products such as paints, coatings, adhesives, and inks.

Applications of Methyl Ethyl Ketone (MEK)

Industrial Solvent

- Paints, Coatings, and Varnishes: Improves drying time and finish quality.

- Adhesives: Enhances bonding for plastics, rubber, and metals.

Pharmaceutical Industry

- Solvent for Drug Formulations: Used in the production of active pharmaceutical ingredients (APIs).

- Extraction and Purification: Helps in extracting and purifying compounds.

Chemical Manufacturing

- Chemical Synthesis: Used to produce chemicals like butanone oxime.

- Extraction: Employed in food, fragrance, and flavor extraction.

Laboratory and Research

- Solvent: Used in chemical reactions and extractions in research labs.

Cleaning and Degreasing

- Metal and Machinery Cleaning: Removes oils and residues in industrial settings.

- Electronics: Cleans circuit boards and components.

Printing and Textile

- Ink Manufacturing: Key solvent for printing inks.

- Textile: Used for cleaning and purifying fabrics.

Environmental Testing

- Pollution Control: Detects and removes contaminants from environmental samples.

Storage Guidelines

- Temperature:

- Store in a cool, dry, well-ventilated area, away from heat sources and direct sunlight.

- Recommended storage temperature: 15°C to 25°C (59°F to 77°F).

- Avoid storing MEK in freezing or excessively high-temperature environments.

- Containers:

- Keep in tightly sealed containers made of compatible materials such as glass or HDPE (high-density polyethylene).

- Ensure that containers are properly labeled to prevent misuse.

- Environment:

- Store away from ignition sources such as open flames, sparks, or static electricity.

- Keep away from strong oxidizing agents, acids, and bases to prevent hazardous reactions.

- Shelf Life:

- MEK is stable for long periods if stored correctly. Refer to packaging for specific expiration dates.

Handling Guidelines

- Personal Protective Equipment (PPE):

- Gloves: Wear chemical-resistant gloves (e.g., nitrile or neoprene) to prevent skin contact.

- Eye Protection: Use safety goggles or a face shield to protect eyes from splashes or vapors.

- Clothing: Wear a lab coat or other protective clothing to prevent skin exposure.

- Respiratory Protection: Use a respirator or dust mask in poorly ventilated areas or if handling large quantities.

- Work Area:

- Handle MEK in a well-ventilated area or under a fume hood to avoid inhalation of vapors.

- Keep the work area clean, organized, and free of non-laboratory items to prevent accidental contamination or exposure.

- Precautions:

- Avoid ingestion, inhalation, and skin contact with MEK.

- Ensure that all containers are tightly sealed when not in use to minimize evaporation and exposure to the air.

- Use non-sparking tools and equipment when handling MEK to avoid ignition risks.

- First Aid Measures:

- Inhalation: Move to fresh air immediately. Seek medical attention if symptoms persist.

- Skin Contact: Wash with soap and water immediately. Remove contaminated clothing.

- Eye Contact: Rinse immediately with plenty of water for at least 15 minutes. Seek medical attention if irritation persists.

- Ingestion: Do not induce vomiting. Rinse mouth and seek immediate medical attention.

Spill and Leak Procedures

- Spill Response:

- Evacuate the area immediately and remove all ignition sources.

- Use absorbent materials (e.g., sand, vermiculite) to contain and clean up spills.

- Dispose of the spilled material and waste according to local regulations.

Disposal

- Dispose of MEK according to local, regional, and national regulations.

- Use licensed chemical waste disposal services to properly dispose of containers and residues.

Additional information

| Size | 100mL (3.3 Fl Oz), 250mL (8 Fl Oz), 500mL (16 Fl Oz), 1000mL (32 Fl Oz) |

|---|

Related products

-

Dihydroterpineol (Menthanol) Aroma/Flavor Compound High Purity

$12.00 – $32.00 Select options This product has multiple variants. The options may be chosen on the product page -

Butyric Acid – FCC Grade

$11.00 – $69.99 Select options This product has multiple variants. The options may be chosen on the product page -

Hydrochloric Acid 37% Premium ACS Reagent Grade

$14.99 – $57.00 Select options This product has multiple variants. The options may be chosen on the product page -

Isopropyl Myristate (IPM) – Premium Grade Emollient

$14.99 – $45.00 Select options This product has multiple variants. The options may be chosen on the product page

SKU: N/A

Category: Solvents (3)

Tags: buy MEK for cleaning, buy Methyl Ethyl Ketone, high-purity MEK, high-purity Methyl Ethyl Ketone, industrial solvent MEK, MEK bulk purchase, MEK bulk supplier, MEK CAS 78-93-3, MEK chemical solvent, MEK chemical solvent for inks, MEK chemical synthesis, MEK cleaning solution, MEK degreasing solvent, MEK fast evaporation, MEK fast-drying solvent, MEK for adhesives, MEK for chemical reactions, MEK for coatings, MEK for coatings and adhesives, MEK for degreasing, MEK for electronics cleaning, MEK for environmental testing, MEK for ink manufacturing, MEK for ink production, MEK for laboratory synthesis, MEK for paint thinners, MEK for paints, MEK for pharmaceutical applications, MEK for pharmaceutical extraction, MEK for pharmaceutical formulations, MEK for polymer manufacturing, MEK for polymer production, MEK for resin applications, MEK for solvent extraction, MEK for surface cleaning, MEK for surface preparation, MEK for varnishes, MEK in automotive industry, MEK in chemical analysis, MEK in chemical extraction, MEK in coating formulations, MEK in environmental science, MEK in research labs, MEK solvent, MEK solvent for cleaning, MEK solvent for degreasing, MEK solvent for industrial use, MEK solvent for laboratories, MEK solvent for pharmaceutical industry, MEK solvent for research, MEK solvent online, Methyl Ethyl Ketone, Methyl Ethyl Ketone for degreasing, Methyl Ethyl Ketone supplier